Murray's law

Murray's law, or Murray's principle is a formula for relating the radii of daughter branches to the radii of the parent branch of a lumen-based system.[1][2] The branches classically refer to the branching of the circulatory system or the respiratory system,[3] but have been shown to also hold true for the branchings of xylem, the water transport system in plants.[4]

Murray's original analysis was intended to determine the vessel radius that required minimum expenditure of energy by the organism. Larger vessels lower the energy expended in pumping blood because the pressure drop in the vessels reduces with increasing diameter according to the Hagen-Poiseuille equation. However, larger vessels increase the overall volume of blood in the system; blood being a living fluid requires metabolic support. Murray's law is therefore an optimisation exercise to balance these factors.

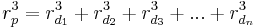

For  daughter branches arising from a common parent branch, the formula is:

daughter branches arising from a common parent branch, the formula is:

where  is the radius of the parent branch, and

is the radius of the parent branch, and  ,

,  ,

,  ...

... are the radii of the respective daughter branches.

are the radii of the respective daughter branches.

Murray's law is seeing increasing use as a biomimetic design tool in engineering - for example it has recently been applied in the design of minimum mass vascular networks carrying a liquid healing agent to areas of damage in a Self-healing material[5] and the expression developed could readily be applied to minimum mass fluid systems in other engineering applications. The trade-off is directly analogous - larger diameter tubes are heavier because of both the tubing and the additional volume of enclosed fluid, but the pressure losses incurred are reduced and so the mass of the pumping system required is lower. The (inner) tube diameter  which minimizes the total mass (tube + fluid + pump), is given by the following equation in Laminar flow [5]:

which minimizes the total mass (tube + fluid + pump), is given by the following equation in Laminar flow [5]:

![d_i^6 = \frac{1024 Q^2 \mu }{ \pi^2 k [ \rho_{tube} (c^2%2B2c) %2B \rho_{fluid} ] }](/2012-wikipedia_en_all_nopic_01_2012/I/6a1b2ad462030f13be076afc3427afa9.png)

where  is the volume flow rate,

is the volume flow rate,  the fluid viscosity,

the fluid viscosity,  the power-to-weight ratio of the pump,

the power-to-weight ratio of the pump,  the density of the tubing material,

the density of the tubing material,  a constant of proportionality linking vessel wall thickness with internal diameter and

a constant of proportionality linking vessel wall thickness with internal diameter and  the density of the fluid.

the density of the fluid.

For Turbulent flow the equivalent relation (derived from the Darcy-Weisbach equation) is [5]:

![d_i^7 = \frac{80 Q^3 \rho_{fluid} f }{ \pi^3 k [ \rho_{tube} (c^2%2B2c) %2B \rho_{fluid} ] }](/2012-wikipedia_en_all_nopic_01_2012/I/22ad669f98a100869bb38efe27a87975.png)

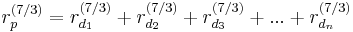

where f is the Darcy Friction Factor. The junction relations above can therefore be applied in the following form in turbulent flow:

References

- ^ Murray, Cecil D. (1926). "The Physiological Principle of Minimum Work: I. The Vascular System and the Cost of Blood Volume". Proceedings of the National Academy of Sciences of the United States of America 12 (3): 207–214. doi:10.1073/pnas.12.3.207. PMC 1084489. PMID 16576980. http://www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=1084489.

- ^ Murray, Cecil D. (1926). "The Physiological Principle of Minimum Work: II. Oxygen Exchange in Capillaries". Proceedings of the National Academy of Sciences of the United States of America 12 (5): 299–304. doi:10.1073/pnas.12.5.299. PMC 1084544. PMID 16587082. http://www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=1084544.

- ^ Sherman, Thomas F. (1981). "On connecting large vessels to small. The meaning of Murray's law" (pdf). The Journal of General Physiology 78 (4): a 431–453. PMC 2228620. PMID 7288393. http://jgp.rupress.org/cgi/reprint/78/4/431.pdf.

- ^ McCulloh, Katherine A.; John S. Sperry and Frederick R. Adler (2003). "Water transport in plants obeys Murray's law". Nature 421 (6926): 939–942. doi:10.1038/nature01444. PMID 12607000. http://www.nature.com/nature/journal/v421/n6926/full/nature01444.html.

- ^ a b c Williams, Hugo R.; Trask, Richard S., Weaver, Paul M. and Bond, Ian P. (2008). "Minimum mass vascular networks in multifunctional materials". Journal of the Royal Society Interface 5 (18): 55–65. doi:10.1098/rsif.2007.1022. PMC 2605499. PMID 17426011. http://rsif.royalsocietypublishing.org/content/5/18/55.full.